Production Technology Level 3

Title of Qualification:

SAQA ID: 58785 National Certificate: Production Technology Level 3

Duration of Qualification:

This programme consists of Fundamental and Elective Unit Standards and will be covered over a period of one year (see breakdown for more information)

Total Number of Credits:123

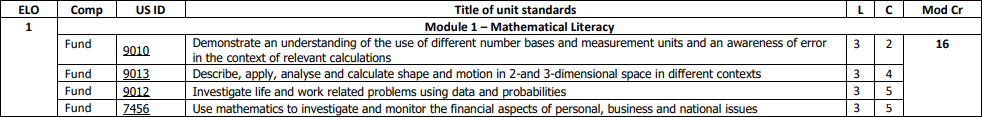

Module 1 – Mathematical Literacy

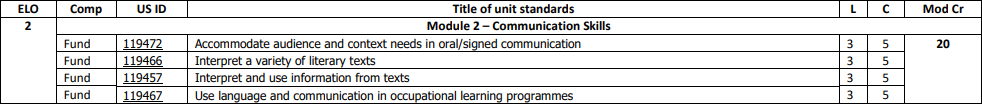

Module 2 – Communication Skills

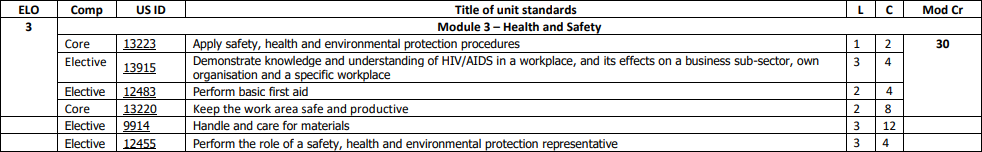

Module 3 – Health and Safety

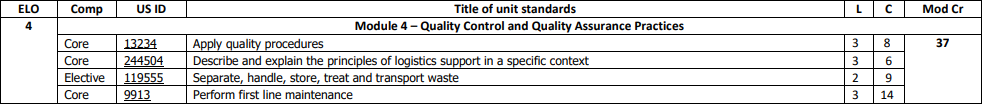

Module 4 – Quality Control and Quality Assurance Practices

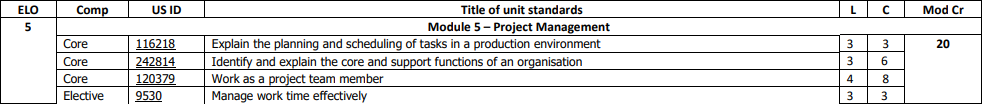

Module 5 – Project Management

The purpose of this qualification is to contributes to the industries in manufacturing and related fields which will allow learners who achieve the qualification to contribute and function in areas such as production planning and control, systems and maintenance, quality and occupational health and safety. Learners who will typically embark on this qualification are individuals who have an interest in a career in production technology. The production technology competencies incorporated in this qualification can also be offered as support skills programmes to incumbents in any other manufacturing, engineering and technology field qualifications.

This qualification will add value to a specific manufacturing, engineering and technology context by complementing contexts specific qualifications within these sectors. The supportive relationship between occupational qualifications and this suite of qualifications is embedded in the inclusion of production technology competencies that have previously not been included in mainstream production, manufacturing and technological qualifications in order to address these identified gaps.

Entry Requirements

It is compulsory therefore for learners to do Communication in two different South African languages, one at Level 4 and the other at Level 3. All Unit Standards in the Fundamental Component are compulsory. The Fundamental Component consists of Unit Standards to the value of 56 credits all of which are compulsory.

Who is the course intended for?

This qualification is intended for a pool of people that can choose a career in a production, engineering, manufacturing field and secondly, to allow any of the manufacturing and related qualifications to utilise the production technology qualifications as entry qualifications in these industries, since they would include the production technology competencies that these industries require. The qualifying learner will also gain access to further learning as a supervisor or in a managerial position within this specific production environment; and lastly, therefore have a learning pathway to access higher education programmes in this discipline.

Learning assumed to be in place and recognition of prior learning

Learners may access this Qualification in terms of Recognition of Prior Learning (RPL), which is subject to quality assurance by the relevant accredited ETQA and is conducted by a registered workplace assessor, subject to the terms of the model decided upon by the relevant ETQA. The qualification is specifically designed to accommodate a broad range of recognition of prior learning. This intention is reflected in the structure of the qualification and in the rules for combination of credits towards the qualification. The intention is to provide recognition for all the relevant skills which learners already possess and even to provide recognition for skills which might not be relevant to the job through the elective category.

The successful candidate will be able to achieve the following outcomes:

1. Perform production maintenance activities and report irregularities within organisational structures.

2. Apply the fundamental concepts, theories and techniques of production systems.

Range: Include, but not limited to, Just in Time (JIT), cycle times, process flow, division of labour, lead times, transport systems, supply chain, value chain, Total Quality Management (TQM), process control, inventory control, batch sizes, capacity, productivity, lean manufacturing, waste management.

3. Apply the fundamental concepts relating to production planning, scheduling and control.

4. Apply quality control and quality assurance practices for efficient and effective production processes.

5. Communicate effectively as a member of a team.